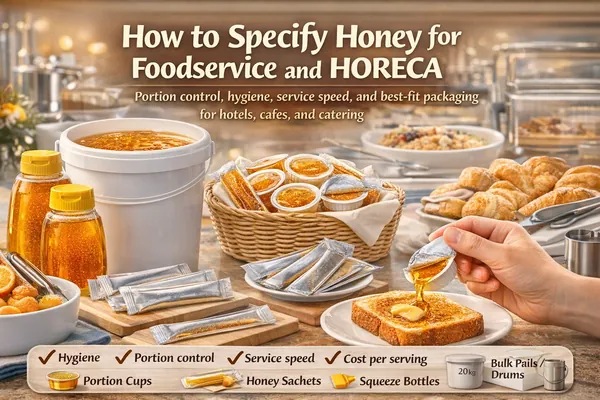

In HORECA, honey selection is typically driven by operating realities: hygiene expectations, guest throughput, staff time, and cost per serving. The right specification reduces waste and speeds service while keeping the guest experience consistent across locations and seasons.

1) Choose the format based on service model

| Service model | Best-fit format | Why it works |

|---|---|---|

| Breakfast buffet (hotel) | Portion cups (single-serve) | Hygiene cues, predictable usage, minimal mess, fast replenishment. |

| Room service / grab-and-go | Sachets / sticks | Portable, easy to distribute, controlled servings and inventory. |

| Table service (cafe) | Squeeze bottle | Speed and convenience; reduces utensil handling and cleanup. |

| Kitchen use (bakery, desserts) | Bulk pails / drums | Lowest handling cost per kg; aligns with production schedules. |

2) Portion control and cost per serving

Portion formats make budgeting easier because consumption is measurable. To build a practical spec, define a target cost per serving and then work backward: serving size, case pack, and monthly volume.

- Serving size target: sized to cover one standard use without excess.

- Case pack efficiency: choose counts that reduce partial cases and storage complexity.

- Waste control: consider guest behavior (buffet vs plated) and disposal patterns.

3) Hygiene and guest perception

Hotels and high-throughput cafes prioritize formats that signal cleanliness and reduce shared-contact points. Single-serve cups and sachets typically perform best for this reason, especially where buffet lines are long.

4) Honey profile: keep it consistent

In foodservice, “consistent and neutral-friendly” profiles often win because they pair with many foods. If you want differentiation, consider a two-tier approach: a core everyday honey for volume plus one premium option for VIP lounges or signature breakfast sets.

5) Documentation and labeling (export readiness)

Foodservice buyers frequently request clear specifications and batch traceability. Requirements vary by destination, but planning early avoids timeline slips—especially for private label or when multiple languages are required.

- Specification sheet and batch information

- Label language and format aligned to the destination market

- Case/pallet markings for warehouse operations