Storage is one of the most overlooked drivers of quality outcomes in honey and bee products—especially when products move through importers, distribution centers, private label packing, or multi-location foodservice programs. Most product complaints that appear “quality-related” are, in practice, handling-related: exposure to moisture, excessive heat, poor closure discipline, or inconsistent cold-chain management for sensitive bee products.

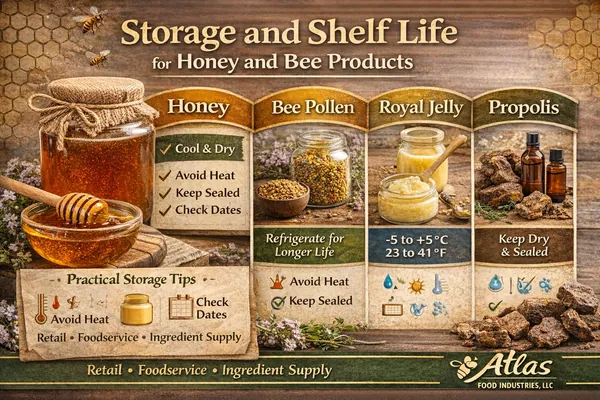

This article provides buyer-friendly guidance on how to store honey, bee pollen, royal jelly, and propolis formats, what shelf life typically means in commercial programs, and which operational controls help you keep product consistent from arrival to end-customer.

Contents

1) Storage principles that apply to all bee products 2) Honey: storage, crystallization, and shelf life 3) Bee pollen: moisture control and quality retention 4) Royal jelly: cold chain and packaging realities 5) Propolis: raw, extract, and finished formats 6) Bulk handling: pails, drums, IBCs 7) Retail and foodservice handling guidance 8) Buyer checklists: receiving and storage SOP 9) FAQ1) Storage principles that apply to all bee products

While honey and bee products differ in sensitivity, most storage success is driven by a few repeatable controls:

- Temperature control: avoid extreme heat and repeated temperature swings that accelerate quality degradation or texture changes.

- Moisture control: protect products from humid environments; moisture can compromise stability, especially in pollen and some propolis formats.

- Light control: protect from direct sunlight and strong ambient light that can reduce sensory quality over time.

- Seal integrity: keep containers tightly closed; prevent odor absorption and moisture ingress.

- Lot discipline: maintain clear lot segregation and FIFO/FEFO rotation in warehouses and production areas.

2) Honey: storage, crystallization, and shelf life

Honey is naturally stable when stored correctly. In commercial markets, “shelf life” is often managed as a best-before quality window rather than a spoilage deadline. Honey’s most common change over time is crystallization, which is normal and not a sign of spoilage.

How to store honey (retail and bulk)

- Store sealed in a cool, dry location away from direct sunlight.

- Avoid storing near strong odors (honey can absorb odors through repeated opening and poor sealing).

- Keep lids closed between uses in foodservice to reduce moisture exposure.

Crystallization: what to tell buyers and end customers

- Crystallization is a natural process that depends on composition and storage conditions.

- For liquid presentation, gentle warming can return honey to liquid form; avoid overheating that can reduce sensory quality.

- For premium “natural” positioning, crystallization can be framed as normal and expected.

| Issue buyers observe | Most common cause | Practical fix |

|---|---|---|

| Crystallized honey | Normal behavior + cool storage | Communicate as natural; warm gently if liquid needed |

| Foam/top layer | Fill/aeration or movement after packing | Improve settling time; handle pallets gently |

| Flavor seems “flat” | Heat exposure or long storage in warm areas | Move to cooler storage; reduce heat cycles |

| Fermentation risk | Moisture ingress or poor closure discipline | Keep sealed; control humidity; avoid wet utensils |

3) Bee pollen: moisture control and quality retention

Bee pollen is more sensitive than honey. The two practical enemies are humidity and heat. Buyers should treat pollen as a quality-managed product that benefits from tighter storage discipline.

Key storage principles for pollen

- Keep pollen sealed and protected from moisture. Avoid opening containers in humid environments.

- Store away from heat sources; prolonged warmth can reduce sensory and functional qualities over time.

- ps: Some commercial programs prefer refrigerated or frozen storage for long-term retention depending on format and internal standards.

4) Royal jelly: cold chain and packaging realities

Royal jelly is typically the most temperature-sensitive product in the bee products family. Many buyer programs maintain refrigerated or frozen storage to preserve freshness and functional properties, particularly when storage durations are long or when the product is distributed across multiple locations.

What to align with your supplier

- Format: fresh/frozen royal jelly, blended forms, or finished consumer products (capsules, mixes) have different handling needs.

- Cold chain expectation: define required temperature range and confirm packaging/shipping method.

- Receiving SOP: record arrival condition and move product quickly into appropriate storage.

5) Propolis: raw, extract, and finished formats

Propolis storage needs depend heavily on format:

Raw propolis

- Store sealed, cool, and dry. Protect from heat that can soften the resin and complicate handling.

- Keep away from strong odors and dust contamination.

Propolis extracts (liquid) and tinctures

- Store sealed and away from direct light; keep caps tightly closed to protect aroma and solvent balance.

- Use FEFO rotation and minimize repeated opening in production environments.

Finished propolis products (sprays, drops, lozenges)

- Follow format-specific storage instructions; protect from heat and direct sunlight.

- In retail, packaging integrity and cap discipline are the main drivers of shelf stability.

6) Bulk handling: pails, drums, IBCs

Bulk storage introduces operational risks: temperature gradients, repeated opening, contamination from tools, and moisture ingress. If you receive honey in bulk for repacking or manufacturing, implement simple controls:

- Seal discipline: reseal immediately after sampling or pumping.

- Sanitary tools: use dry, clean sampling tools; avoid introducing water or residues.

- Lot segregation: do not “top up” partially used containers with a new lot unless your system captures blending rules.

- Temperature management: plan gentle warming only if needed for pumping; avoid excessive or prolonged heating.

| Bulk format | Typical advantage | Main handling risk |

|---|---|---|

| Pails | Flexible, easy to move | Frequent opening increases moisture/contamination risk |

| Drums | Efficient for medium volumes | Sampling discipline; heating/pumping mismanagement |

| IBC | High-volume efficiency | Requires proper pumping setup and controlled storage environment |

7) Retail and foodservice handling guidance

The difference between retail and foodservice storage is frequency of opening and exposure:

Retail

- Keep products away from direct sunlight (front-window displays are a common quality risk).

- Rotate by FEFO. Make sure staff can read lot/best-before marks on cases.

- For premium lines, minimize warm storage that dulls aroma over time.

Foodservice

- Use portion cups or controlled dispensers when hygiene and consistency matter.

- Keep lids closed; avoid wet utensils contacting honey.

- Train staff that crystallization is normal—swap formats if your service requires continuous flow.

8) Buyer checklists: receiving and storage SOP

Receiving checklist (importer/warehouse)

- Inspect pallet and case condition (leaks, crushed cartons, heat exposure signs).

- Verify lot codes match packing list and COA (when applicable).

- Take photos of pallet labels and lot markings for traceability.

- Move products immediately to correct storage zones (ambient vs cold chain products).

Storage SOP checklist

- Define zones: ambient honey, pollen, royal jelly (cold), propolis formats.

- Implement FEFO rotation and maintain lot segregation.

- Control humidity in pollen storage areas where feasible.

- Maintain closure discipline (reseal after sampling/dispensing).

9) FAQ

Does honey expire?

Honey is naturally stable when stored sealed in a cool, dry place. Many markets use a best-before date to manage quality. Crystallization is normal and does not mean honey is spoiled.

How should bee pollen be stored?

Pollen is sensitive to moisture and heat. Keep it sealed and dry, away from humidity. Depending on format and buyer program, refrigerated or frozen storage may be preferred for longer-term quality retention.

Does royal jelly require cold chain?

Royal jelly is more temperature-sensitive than honey. Many programs store it refrigerated or frozen to maintain freshness and functional qualities, especially for longer storage or extended distribution.

Is crystallization a quality defect for honey?

No. Crystallization is a natural characteristic of honey and is influenced by composition and storage temperature. If your channel requires consistently liquid honey, align packaging choice and rotation speed accordingly.

What is the biggest storage mistake buyers make?

The most common mistakes are storing products in warm areas (near heaters or in direct sun), leaving containers unsealed after sampling, and failing to segregate lots. Simple SOPs prevent the majority of issues.